200,000HL BREWERY (EXTENDIBLE TO 300,000 HL P.A)

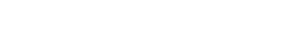

MALT HANDLING

- Malt conveyors, silo inlet and elevators, make Bühler, built 2012 / 2010 / 2005

- Pour scale, make Hense Wägetechnik, digital, built 2005

- Magnetic sieve, make Bühler, built 2010

- Stone removal, make Bühler, type: MTSC 65/120 E, built 2010

- Dust removal, make Bühler, built 2010

- Malt scale, make Bühler, type: MSDL 40, built 2012, digital

- Malt conditioning, make Bühler, built 2012

- Malt steeping tank after conditioning, make Bühler, built 2012

- Malt mill, make Bühler, type: Maltomat 07 DBZC-07, with 6 roller, built 2010

- Grist case

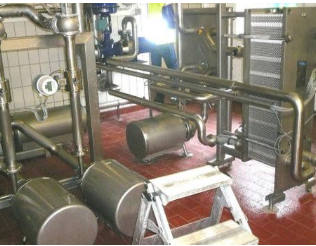

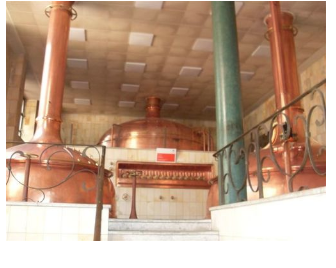

BREWHOUSE EQUIPMENT

4-vessel brewhouse, make Ziemann, in 2002 partly modernized and automated through Nerb, for at time 270 hl / brew cast wort by 5.100 kg/grist (max. ~ 320 hl by 6.000 kg/grist), consisting of:

- Mash copper, in stainless steel, built 2002, with bottom- and wall heating, close top bottom, isolated

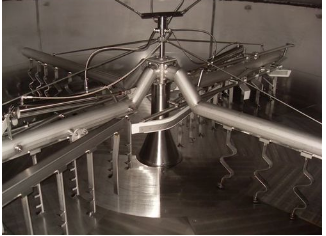

- Lautertun, complete in stainless steel, assembled behind the wall, modernized in 2002 with new false bottom in stainless steel and in 2007 with new 4-arm height adjustable raking and spent grains removal machine, with 6 knife-bars in stainless steel, drive from below, with central lautering, isolated, standing on steel construction, inside-Ø: 5,79m

- Wet grains buffer tank

- Preruntank (former Wort kettle), complete in stainless steel, assembled behind the wall, in rectangular industrial construction, in 2002 modernized

- Wort heater as plate apparatus make API Schmidt Bretten, type: SIGMA 66-1 TBV, 1- stage, 10 bar, built 1998

- Wort kettle / Whirlpool, make Nerb, with 330 hl using content (445 hl total content), softly-isolated and covered with stainless steel sheet, built 2005, Ø: 5,0m, with dome lid, with valve block, pump

- Hop dosage station, make Huppmann, with 2x 205 lt. tanks, in stainless steel, 3 bar, built 1985, with Fristam-Pump

- Brewhouse control, make Nerb, built 2002

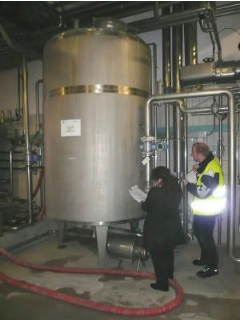

- CIP-Plant, make Nerb, automated, with 4 tanks each 32 hl, standing, in stainless steel, 2 tanks softly-isolated, with manway, armatures, multi tube heat exchanger, pumps, etc., built 1998

- Spent grains silo, make Vetter, with ~ 36 m³ content, standing outdoor, built 2005

- Hot water tank, make Gross, with 954,10 hl content, in stainless steel, softly-isolated and covered with trapezoid sheet, standing on stainless steel notch, built 2009

- 3 Hot water pumps make Hilge, steam regulation valves, WAT for post heating

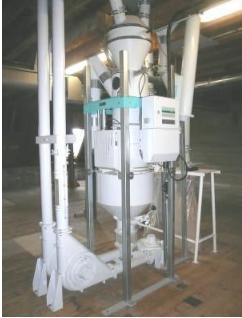

WORT COOLING

- Whirlpool, Nerb, 445 hl, Pumpe, Bj. 2005

- Sludgetank, make Ellinghaus, with 28,10 hl content, cylinder-conical, standing, in stainless steel, with cooling jacket, dome lid, built 1979

- Wort cooler, make API, type: SIGMA 66 SBV, for 350 hl/h, 1-stage, 10 bar, built 2006

FERMENTING- AND STORAGE CELLAR

- 9 cylinder-conical fermenting-/storage tanks, in stainless steel, outdoor standing, isolated and covered, coolable by glycol, with swivelling cone, armatures, of them:

- 2 x 2.300 hl, make Schmidding, built 1973, with 3 cooling zones (2x wall + 1x cone), cone not isolated, with swivelling cone point

- 3 x 2.300 hl, make Ziemann, built 1977, with 3 cooling zone (2x wall + 1x cone), cone isolated, with swivelling cone point

- 3 x 2.300 hl, make Baur, built 1991, with 4 cooling zones (3x wall + 1x cone), cone isolated, with swivelling cone point

- 1 x 1.500 hl, make Gross, built 2008, with 3 cooling zones (2x wall + 1x cone), cone isolated

- Temperature control

- 4 pumps

- Beer deep cooler, plate apparatus, make Schmidt Bretten, type: SIGMA M 27 SBN, 1- stage, 10 bar, built 1998

- Requires Valves and CIP set

FILTRATION

- Separator, make Alfa Laval, built 1991

- Buffer tank for unfiltered beer, make Gross, with 65,30 hl content, 2 bar, standing, in stainless steel, built 1998

- Kieselguhr-Filter, make Schenk ZHF, type: STR 50C 3, horizontal sieve filter

- KG-Dosage, with agitator, dosage pump

- Kieselguhr-tank for old kieselguhr, make Hild, cylinder-conical, standing, in stainless steel

- Buffer tank for filtered beer, make Filtrox, with 670 lt. content, 5 bar, standing, in stainless steel, built 1998

- Trap filter, make Filtrox

- Blending- / final carbonization plant, make APV, built 2010, with laser refractometer ACM, Carbosensor ACM, with Siemens Simatic control, with pump

- Flash pasteurizer, make KHS, type: Eurocal 61 MP, 16 bar, built 1996, in 2000 rebuilt through Fischer, with 4-stage plate heat exchanger, IDM, pumps, control over filter cellar

- Hot caustic tank, make Gross, with 54,5 hl content, standing, in stainless steel, with dome lid, built 1998, with pump

CO2-RECOVERY

Seeger, for 150 kg/h, with:

- Co2-collecting balloon, 25m³ content, built 2005

- Co2-fome separator II

- Co2-washer

- 2 activated carbon cleaner, each 430 lt. content, 20 bar, built 1992

- 2 dryer, each 117 lt. content, 20 bar, built 1991

- Ultra-filter

- CO2-compressor, make Mehrer, type: TZW 50, for 150 kg/h, 15 kW, 620 U/min, built 2011

- CO2-Tank, approx. 20 to content, outdoor standing

- Control

- Cooling compressor, make Sabroe, built 2004, including compressor control

Price: On request Euros, GBP or USD ex works as is excluding dismantling, packing and loading.

The information provided is for guidance only and the buyer should check all details upon inspecting the line

Categories: Equipment for sale, Quality Used Equipment, Used Breweries